Fabrication Process

Fabrication Process

Turning Raw Stone Into Functional Art

What Our Fabrication Process Includes

Natural Stone Surrounds

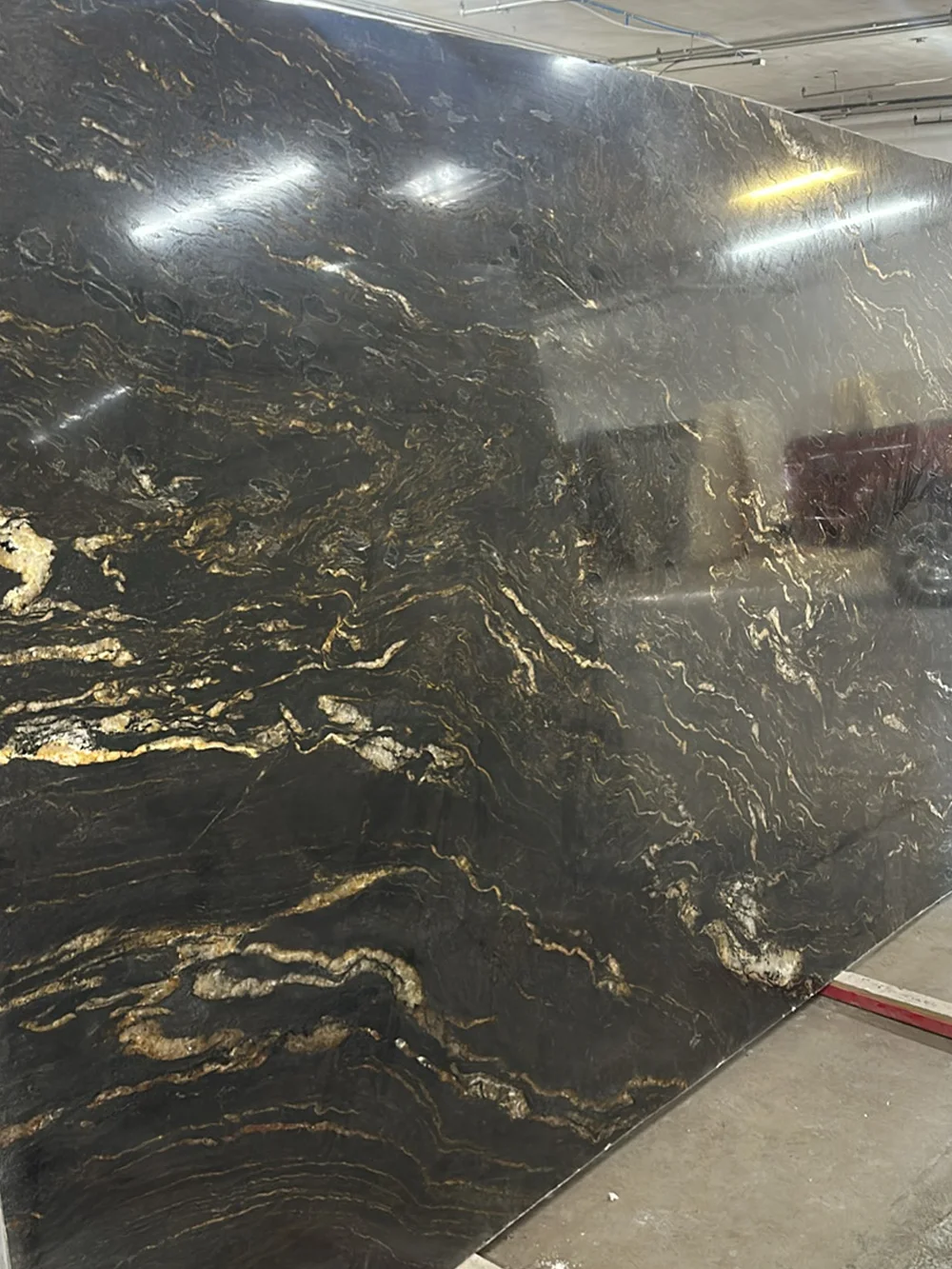

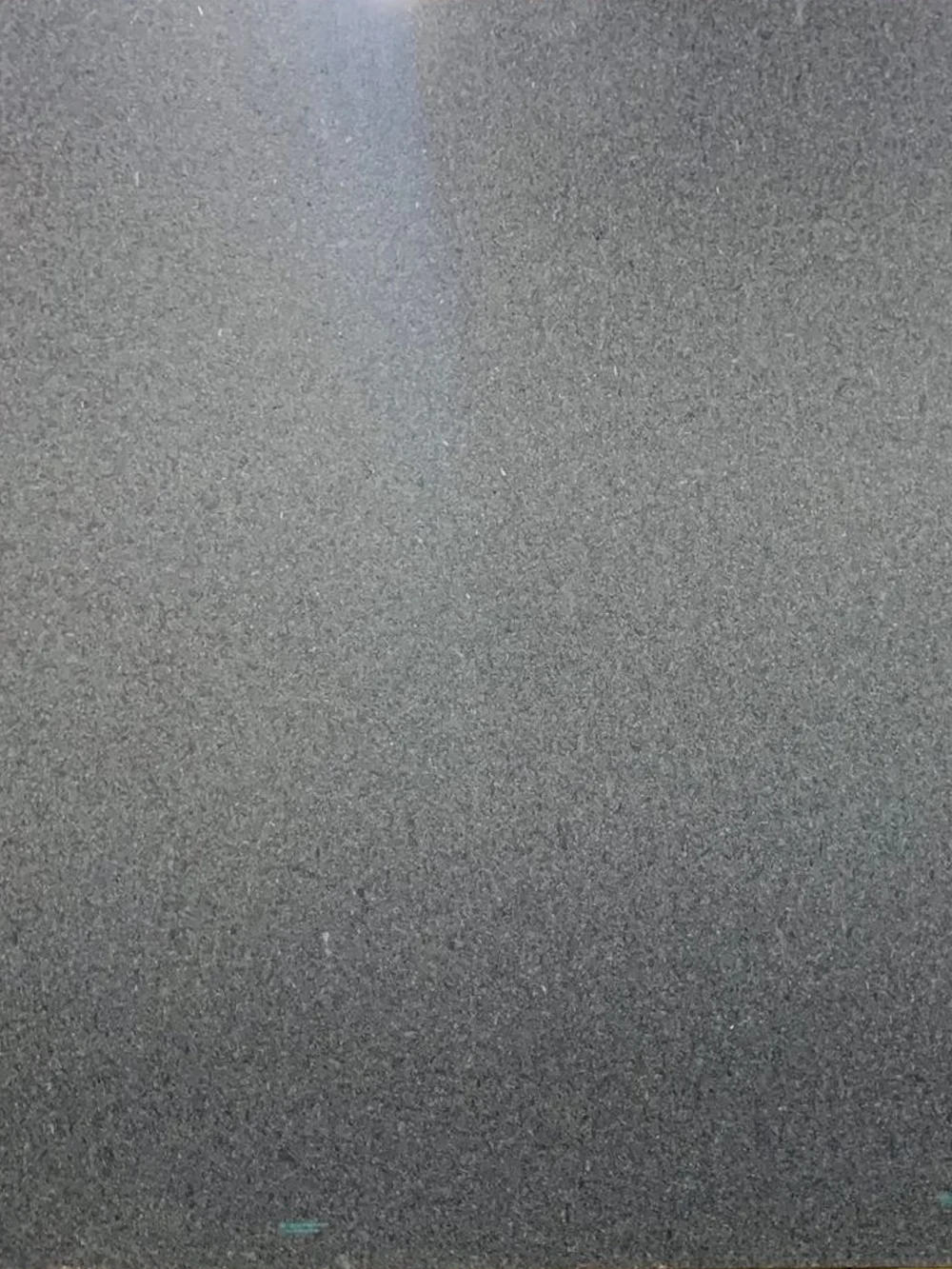

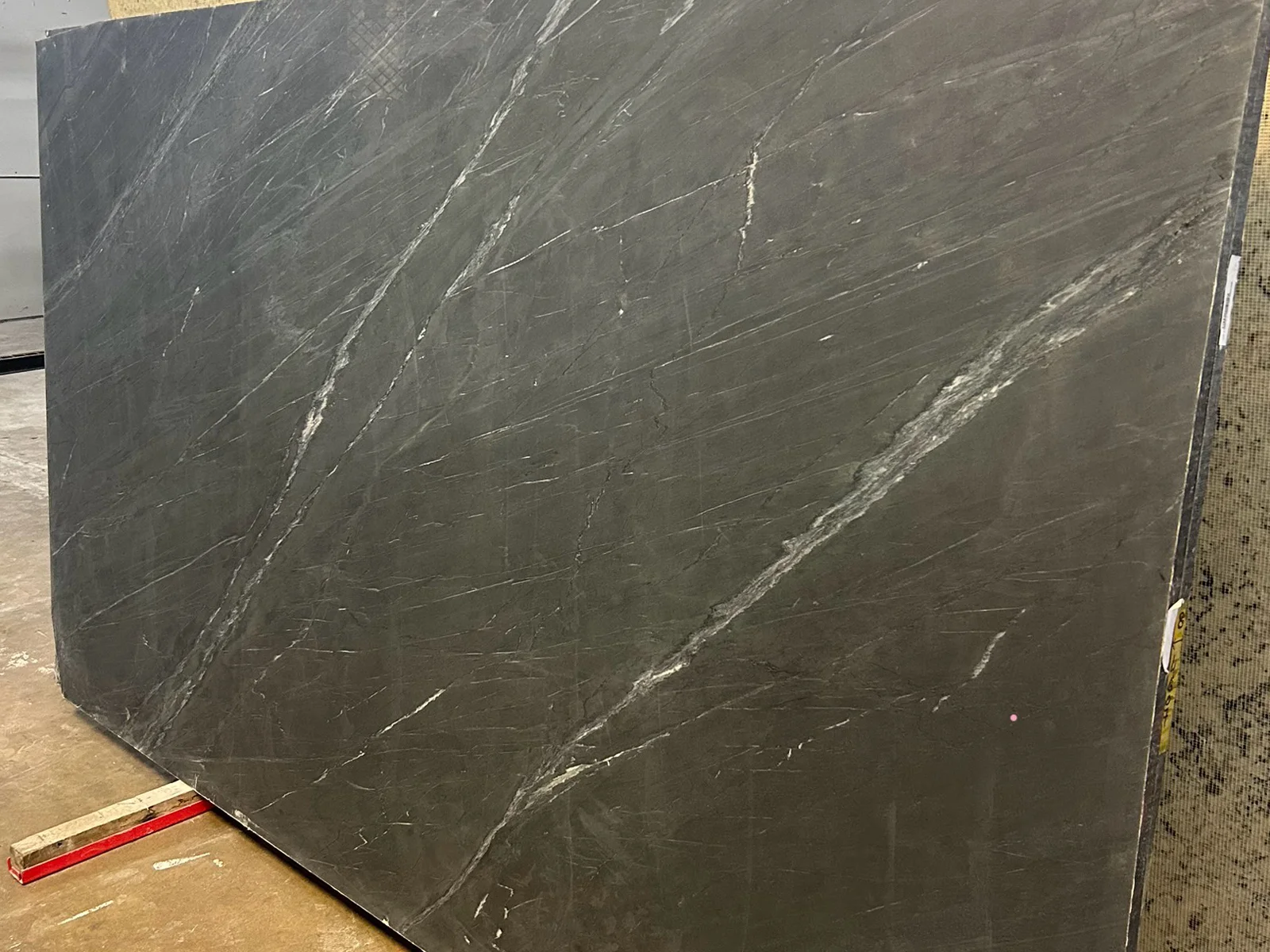

Choose from granite, quartzite, marble, and more

Precision Fabrication

Built in-house with meticulous attention to detail

Tailored Design

Mantels, hearths, and surrounds designed for your space

Indoor & Outdoor Options

Bring comfort to living rooms, patios, or guest areas

Why Choose Lion StoneWorks?

Skilled Stonework

Decades of experience in custom stone fabrication

Premium Materials

We source and cut only the highest quality stone

Collaborative Process

We work directly with homeowners, builders, and designers

Made for Colorado

Built to stand up to local climates and design preferences

Crafting Excellence in Denver, One Project at a Time

At Lion StoneWorks, our fabrication process is more than cutting and shaping stone—it’s where creativity meets craftsmanship. We blend state-of-the-art technology with skilled hands to ensure every piece is crafted with precision, care, and attention to detail.

From the initial design to the final polish, our team works closely with clients to bring their vision to life. Whether it’s a fireplace, countertop, or custom feature, our fabrication process guarantees lasting quality, flawless finishes, and a product that’s as functional as it is beautiful.

Transform Your Space with

the Warmth of Stone

Testimonials

Lauren

I had a great experience working with Lion Stone Works to get new countertops in my kitchen. The project was a tricky one because my house is old and quirky — the team at Lion Stone Works was meticulous and paid attention to every detail, making it look like there were never any quirks in the first place! I couldn’t be happier with the work they did and the professionalism they demonstrated the entire duration of the project. Thank you all!

Vanessa Empire

Jorge and Liz are amazing! This is a family business, and these two are so great to work with! Their assistance in selection was amazing. Liz dropped everything to help me come to a quick decision and to take me to look at slabs. In the end, they had a beautiful piece of Taj Mahal, which I am so glad I went with. Their attention to detail, along with my unusual requests for the shape of the splash was embraced and happily accommodated. Liz was excited and knowledgeable about helping me with my project- I stopped by their showroom on a whim, and I am so glad I did. (She is also one of the funniest people I’ve ever met!) I am looking forward to doing more rooms in my house with them. Thank you for the great work you do!

Keiley Helges

Lion Stone Works did an excellent job replacing our countertops and installing a new backsplash in our kitchen. We received a few different quotes and they were the most affordable. Liz, Tony, and team were great to work with and excellent communicators at every step of the way. I would definitely recommend working with Lion Stone